1st ever RMC Plant in Tirupati

Building Trust with Every Pour

As the trailblazers in the realm of ready-mix concrete manufacturing in Tirupati, we pride ourselves on being at the forefront of innovation and excellence. With over a decade of unwavering dedication, we have been the backbone of countless construction projects, ensuring they stand the test of time. Our extensive experience of 12 years in the industry is testament to our expertise and reliability.

Precision & Innovation

30 Years Of Undefeated Success

Welcome to Harini Ready Mix Concrete. Harini group is a pioneer in the construction field having its activities in Tirupati & Bangalore. We are well experienced in building apartments, residential complexes, commercial buildings and public buildings. Now with a vision of expansion, we have started manufacturing ready-mix concrete in the name of HARINI READYMIX CONCRETE in Tirupathi to cater for the growing needs of this potential city.

500+

Commercial projects,

30+

Years of experience with proud

8+

Products

1500+

Happy Homes

About Us

Building Tomorrow's Structures Today with Harini RMC!

Harini Group, established in 1986 in Tirupati, is a leading construction company known for its innovative techniques, quality, and sustainability. Specializing in residential flats, commercial complexes, and infrastructure projects, the company integrates cutting-edge technology to deliver exceptional results. Harini Group’s journey includes setting up Tirupati’s first RMC plant and an automated brick manufacturing unit, achieving self-reliance in construction materials. With eco-friendly practices like solar power and recycling systems, the company prioritizes sustainability. Led by a visionary leadership team, Harini Group is expanding its operations to Bangalore, Hyderabad, Vizag, and Chennai, aiming to be a trusted partner in construction solutions.

Quality Meets

Grades of Concrete

Grade M10: PCC (Plain Cement Concrete)

Leveling Course, Bedding For Footing, Concrete Roads, Etc.

Grade M15: PCC (Plain Cement Concrete)

Leveling Course, Bedding For Footing, Concrete Roads, Etc

Grade M20: RCC (Reinforced Cement Concrete)

Slabs, Beams, Columns, Footings, Etc. (For Mild Exposure)

Grade M25: RCC (Reinforced Cement Concrete)

Slabs, Beams, Columns, Footings, Etc.

Grade M30: RCC (Reinforced Cement Concrete)

Slabs, Beams, Columns, Footings, Etc.

Grade M35: RCC (Reinforced Cement Concrete)

Slabs, Beams, Columns, Footings, Etc.

Grade M40: RCC (Reinforced Cement Concrete)

Pre-stressed Concrete, Slabs, Beams, Columns, Footings, Etc.

Grade M45: RCC (Reinforced Cement Concrete)

Runways, Concrete Roads (Pqc), Prestressed Concrete Girders, Rcc Columns, Spans Prestressed Beams.

Sustainability

Committed To Keep Constructions Strong & Safe

With a commitment to precision, we utilize advanced technology and sophisticated machinery to ensure each mixture meets exact client specifications.

We Follow Best Practices

Harini Ready Mix Concrete excels by leveraging its extensive construction expertise to deliver high-quality concrete solutions.

- Expertise in Construction

- Commitment to Delivery

- Utilization of Advanced Technology

- Focus on Customer Satisfaction

Uncompromising Quality Assurance

Ensuring Excellence, One Test at a Time!

Our Clients

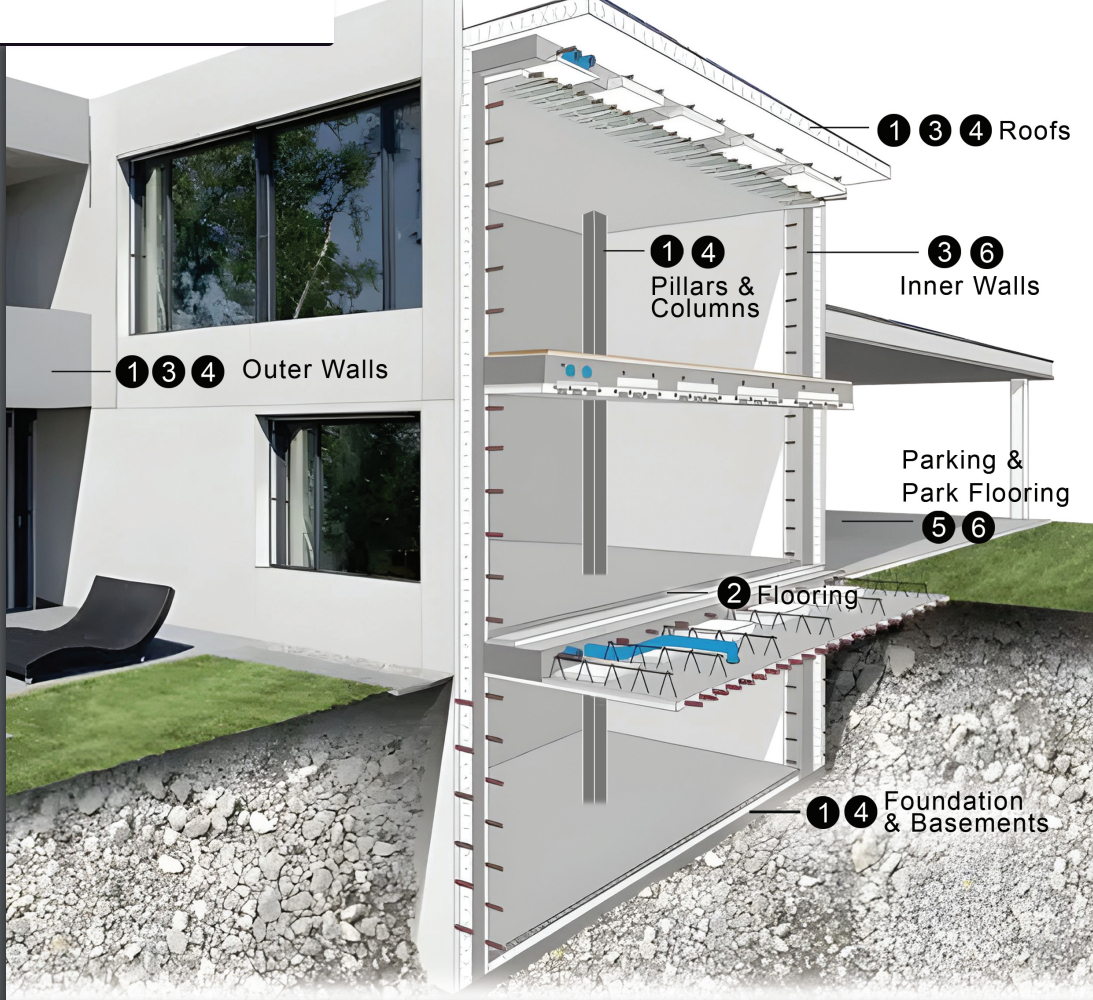

Products with value additions for the mid-high-rise market

Personalized Product Offerings

QuickCrete offers rapid setting times, making it ideal for time-sensitive projects where speed is essential without compromising on strength and durability.

Designed for flooring applications, FloorCrete provides a smooth finish and excellent load-bearing capacity, ensuring long-lasting and aesthetically pleasing floors.

Reinforced with fibers, FibreCrete enhances structural integrity and crack resistance, perfect for projects requiring additional durability and strength.

Self-leveling and easy to apply, SelfCrete is perfect for creating perfectly even surfaces, saving time and labor in large-scale flooring projects.

Engineered for excellent permeability, PoreCrete is ideal for sustainable construction, allowing water to pass through while maintaining structural integrity.

ArtCrete blends functionality with aesthetics, offering customizable patterns and colors for creative architectural designs without sacrificing performance.

EXCELLENTTrustindex verifies that the original source of the review is Google. Excellent Reponse and Amazing service. Utilized the concrete for the Slab of a residential building and I’m completely satisfiedPosted onTrustindex verifies that the original source of the review is Google. Best and most convenient on time service providers ever, we are very satisfied with the quality. Our best wishes to Harini RMCPosted onTrustindex verifies that the original source of the review is Google. Great service, Good QualityPosted onTrustindex verifies that the original source of the review is Google. Reached out HRMC team for slab work. Team was proficient and Efficient. Would recommend if you're interested in saving time and better finish with reasonable pricing.Verified by TrustindexTrustindex verified badge is the Universal Symbol of Trust. Only the greatest companies can get the verified badge who has a review score above 4.5, based on customer reviews over the past 12 months. Read more

Learn More From

Frequently Asked Questions

The concrete has to be tested to know the strength at 28 days for each desired grade. Usually the concrete made at site is not tested for its strength, workability, yield and other factors which ensure the performance of concrete over a period of time. However in Harini readymixx concrete, the samples of concrete are tested for every batch to ensure consistent quality and supply of durable concrete.

Concrete cube moulds having size 15x15x15 cms are casted with sample concrete, cured in water tank for 7 and 28 days and crushed in compressive testing machine at 7 and 28 days to measure compressive strength of concrete.

We suggest you to prefer concreting at early morning or at evening to avoid shrinkage cracks to an extent. Because environmental conditions conductive to high evaporation rates such as low humidity, high temperature, direct sun light and drying winds on a concrete surface cause rapid surface drying resulting in cracking.